HOW DO I CHOOSE A BARCODE LABEL?

HOW DO I CHOOSE A BARCODE LABEL?

FEATURES - SPECIFICATIONS - TECHNICAL INFORMATION - CATEGORIES

We offer a wide range of sizes and types of thermal labels for all barcode printers: ZEBRA, GODEX, SATO, BIXOLON, TSC.

See here our available dimensions:

label dimensions BLP CONNEXION

However, the most commonly used categories of labels are:

-

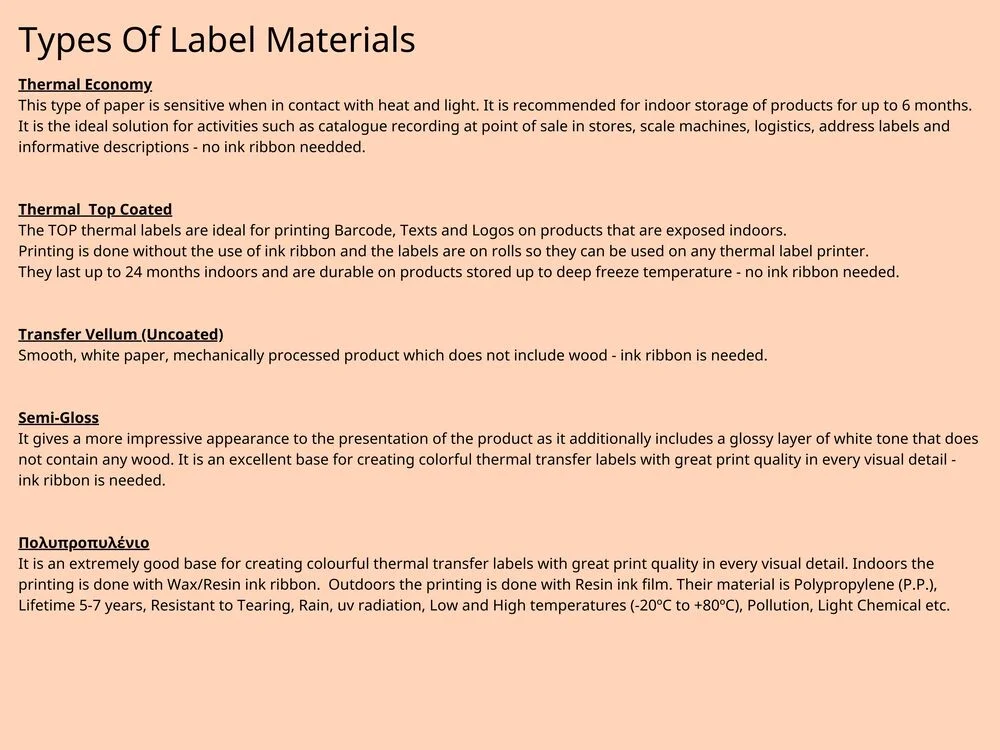

ECO Thermal Labels: The ECO thermal labels are an excellent solution for printing on products such as (barcode, text, logo) which are located indoors. No ink ribbon is used. These rolls can be used on any thermal label printer.The lifetime of both, label and the print will remain unharmed for 6 months.They are also resistant for products stored in refrigeration at 5°C for a period of 5 days.

-

Transfer vellum labels: Transfer vellum labels are printed using ink ribbon. Thermal transfer labels provide us with a longer life span, up to 60 months. This is an ideal solution for use on products, boxes, parcels, shelves, etc.

-

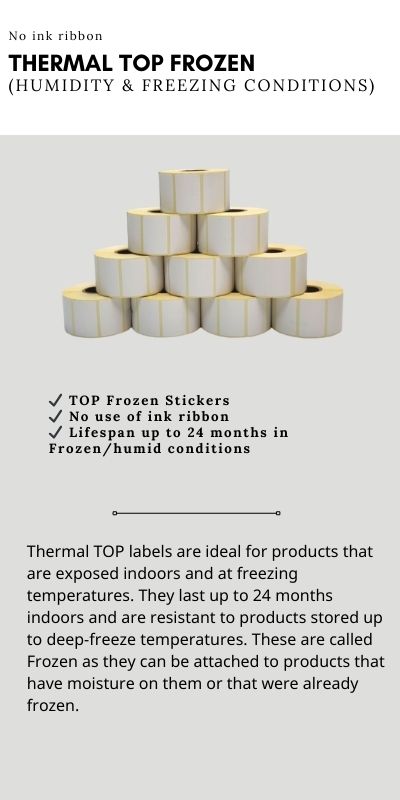

Thermal top labels: They have a long lifespan, up to 24 months for indoor use and are highly resistant to low temperatures. Excellent solution for frozen products that are even at deep-freezing temperatures. Their printing technology is direct thermal so they do not require to use ink ribbon.

-

Plastic labels (PP/PE labels): Plastic labels are printed using resin ink and wax/resin ink ribbon. They have a long shelf life and give a premium look to the products. They also demonstrate humidity and tear resistance. Construction material: (P.P.) polypropylene.

-

Removable thermal/thermal transfer labels:The main feature of this category of labels is the special glue which makes it easy to peel and reapply the labels. They can be either thermal or thermal transfer depending on the type of paper. Its special feature makes it ideal for temporary labelling, pharmacies or drug stores.

Below is a detailed description of the different types of labels that exist and that you can order at BLP CONNEXION.

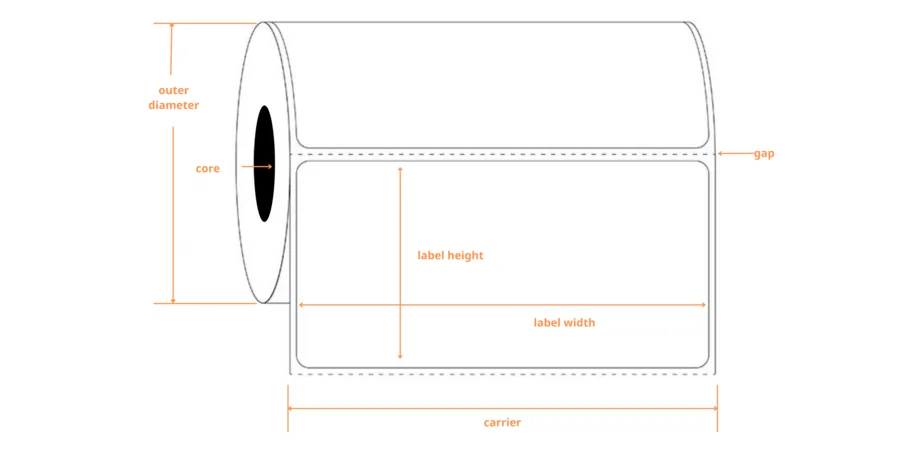

NATURAL FEATURES OF THE LABEL ROLL - DIMENSIONS

✔️Gap: the small gap that separates one label from another on the roll.

✔️Gap: the small gap that separates one label from another on the roll.

✔️ Core: the core is the diameter of the empty space in the center of the label roll. Depending on the type of printer there are corresponding core diameters. (e.g. f20-f40-f76)

✔️ Label Height: the height of each label on the roll from the top edge to the bottom. The label height, of course, determines the number of labels per a given roll length.

✔️ Label Width: the distance from one side to the other. The capacity of each printer model determines the allowed roll width and therefore the label width. 4-inch printers produce narrower labels (e.g. 108mm) than 6-inch printers (e.g. 168mm).

✔️ Outside Roll Diameter: is the diameter of the entire body of the roll. Note that some roll diameters may be quite large for a particular type of printer. A fact that should draw our attention when ordering label rolls.

✔️ Silicon paper: the labels touch the surface of the silicon paper, which is only slightly wider than the label itself, for easy peeling

Barcode printing is a printing used in all services, industries and with many different materials and variations.

In addition, printing a barcode to achieve the desired and effective readability requires the right choice of print media, material reliability and knowledge of the environment and product usage.

Depending on conditions and use, there may be failures such as material fading or smudging.

So we have a barcode that cannot be read and is virtually useless.

Therefore, there are many factors that affect the quality of the print and barcode label, and we need to consider various criteria before deciding on a barcode label for our business.

⇓

Details.

__________________________________

-

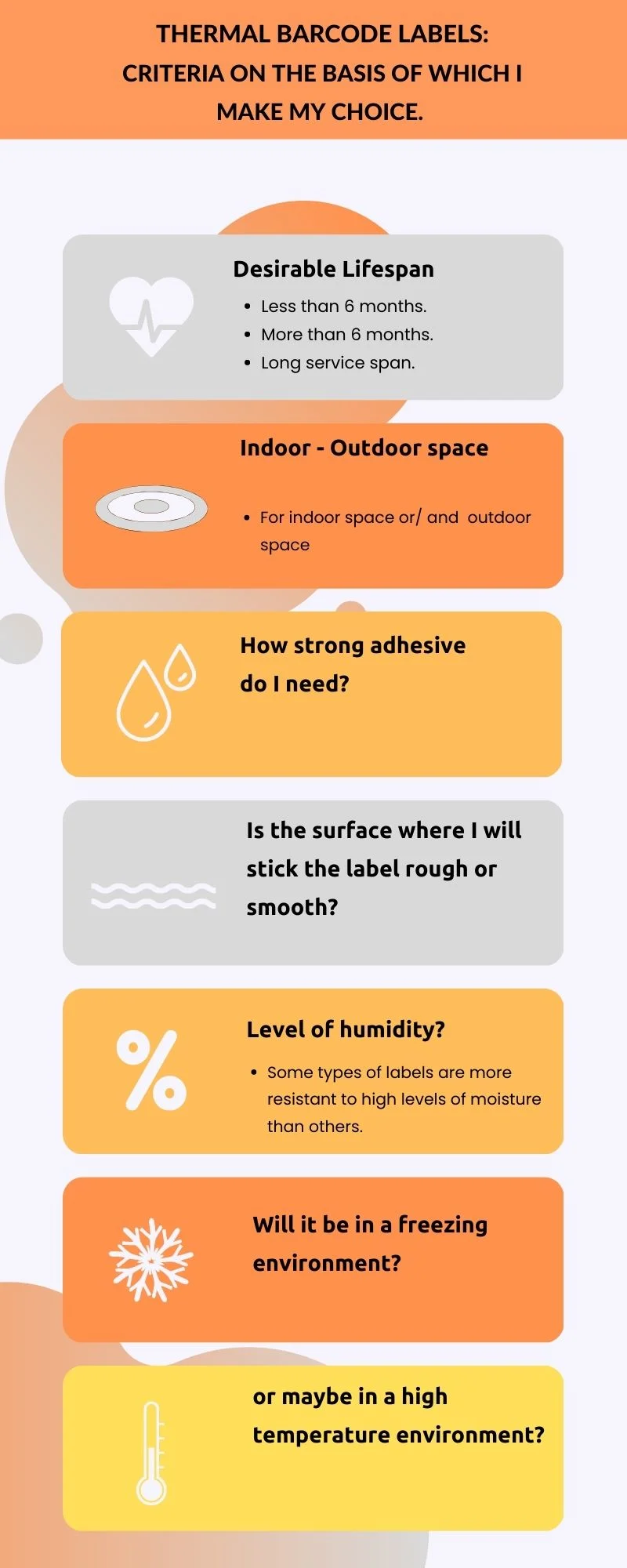

What is the shelf life that I need for the barcode labels?

The product and service cycle varies from industry to industry.

Direct thermal labels are a good and sensible choice for fast-moving and fast-selling products that require a shelf life of less than 6 months. However, due to the fact that they are heat sensitive, they are not recommended for use for more than 1 year.

If your products are going to be stored for more than 6 months, then you will need thermal transfer labels, which are time resistant.

-

What are the environments in which the label will be exposed?

The Direct Thermal label is recommended for indoor applications. The ECO label is sensitive to light and temperature and therefore has a very short outdoor life.

For indoor and/or outdoor applications, Thermal Transfer labels offer the reliability of the material required for barcode printing. Thermal transfer labels are more suitable for outdoor use than direct thermal labels. However, when products are exposed outdoors, in harsh environments and weather conditions, you need a label with exceptional durability. In this case, we recommend a non-paper label made of propylene (P.P.), which is best suited for harsh weather conditions.

-

Do you need a label that is repositionable?

Each type of label roll can be produced with your preferred adhesive.

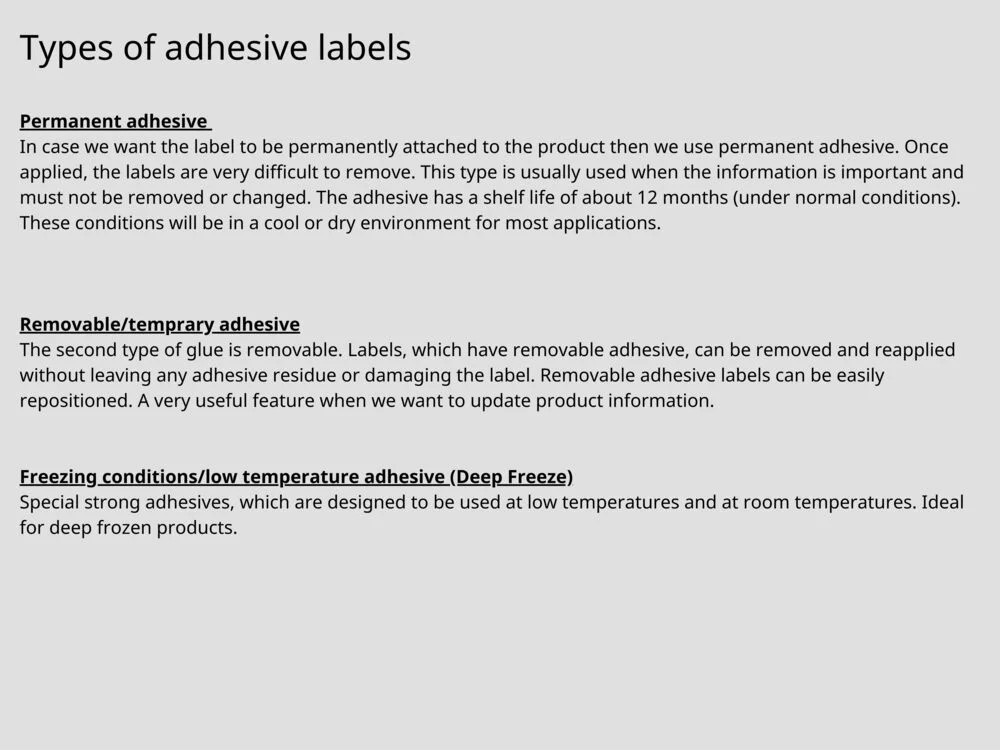

Permanent: If we want the label to be permanently attached to the product, we use a permanent adhesive. Once applied, the labels are very difficult to remove.

Removable: The second type of adhesive is removable. Labels with removable adhesive can be removed and re-applied without leaving adhesive residue or damaging the label. Removable labels can be easily repositioned. A very useful feature when we want to update product information.

-

What is the texture of the surface the label will be applied to?

Depending on the surface to be bonded, the appropriate adhesive or material should be used. A surface can be rough, smooth, frozen or wet. Rough, uneven and wet surfaces require the use of a stronger adhesive. In harsh weather conditions with exposed products, in addition to the correct choice of adhesive, it is preferable to use a polypropylene or polyester label rather than paper.

-

What temperature will the label be exposed to?

Depending on its environment and technical specifications, each adhesive will tend to behave differently. An adhesive may be designed to work well in a frosty environment but not so well in a warm environment and the reverse.

|

|

ACCORDING TO THE ABOVE CRITERIA, THERE ARE THE FOLLOWING CATEGORIES

WHICH ALSO RESPOND TO DIFFERENT MARKET NEEDS.